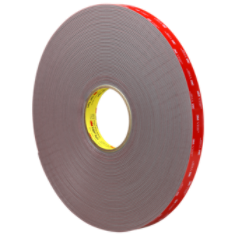

3M VHB Tapes: In the world of industrial and design engineering, the importance of efficient fastening methods cannot be overstated. For years, traditional methods such as rivets, screws, bolts, and welds have been the go-to options. However, a revolutionary alternative has emerged that has changed the lives of engineers forever – 3M VHB Tapes. These high-strength, double-sided acrylic foam tapes have opened up a world of new possibilities, offering superior bonding strength, durability, and ease of application.

The Power of 3M VHB Tapes: Dream, Design, Deliver

Superior Bonding Strength

3M VHB Tapes distributes dynamic or static stress over the entire surface of the design, resulting in impact resistance and dampening vibration. This unique property reduces wear-and-tear on metallic components and creates an exceptionally tight seal. What’s more, the bond strengthens over time, eliminating the need for mechanical fasteners.

Durability and Elasticity

Bonds made with 3M VHB Tapes exhibit exceptional durability, withstanding extreme temperature fluctuations, UV light, moisture, and solvents. Its viscoelastic properties enable it to absorb energy, providing protection against moisture, dirt, and chemicals. This durability ensures a long-lasting bond that can endure harsh conditions.

Ease of Application

One of the key advantages of 3M VHB Tape is its ease of application. Unlike traditional methods that require cure time, welding, or grinding, this tape requires zero cure time. It is easy to use, apply, and cut to precise shapes and sizes, making it suitable for custom applications. The tapes bond and seal on contact, simplifying the assembly process.

Innovative Designs

3M™ VHB™ Tape opens up a world of innovative design possibilities. It bonds to dissimilar materials, preventing bi-metallic corrosion and ensuring compatibility across various substrates. Furthermore, it creates a smooth and clean finish with no trace of pocks or punctures, enhancing the overall aesthetics of the final product.

Impacting Industries Everywhere

3M™ VHB™ Tape has found applications across various industries, revolutionizing the way engineers approach their projects. Let’s explore some of these industries:

Transportation: Dampening Vibration for a Quieter Ride

With 3M™ VHB™ Tape, engineers can design vehicles that can withstand extreme conditions on the open road. By eliminating the added weight of mechanical fasteners, the tape keeps the vehicle’s sides smooth for decals. Additionally, it dampens vibration, resulting in a quieter and more comfortable ride.

Metal Fabrication: Fast and Easy Assembly

In the realm of metal fabrication, 3M™ VHB™ Tape offers a faster and easier alternative to traditional methods. By eliminating the need for riveting and welding, which are time-consuming and vulnerable to corrosion, the tape simplifies the bonding process. It bonds and seals in one step, boosting productivity on the assembly floor.

Construction: Efficient and Long-Lasting Bonds

Architects rely on the strength and quality of 3M™ VHB™ Tape to streamline construction processes. The tape permanently adheres one substrate to another, eliminating the need for labor-intensive methods. Its ability to distribute stress load ensures long-lasting bonds, making it an ideal choice for various construction applications.

Electronics: Design Flexibility and Shock Resistance

In the electronics industry, 3M™ VHB™ Tape meets the highest standards. Its viscoelastic properties provide shock and vibration resistance, making it suitable for bonding delicate electronic components. The tape has been successfully used in applications ranging from high-definition television screens to moisture-sealed nautical navigational systems, showcasing its versatility and reliability.

Signage: Secure and Aesthetically Pleasing Bonds

When it comes to signage, 3M™ VHB™ Tapes offer a hassle-free solution. By eliminating the need for screws and the curing time of liquid adhesives, these tapes simplify the installation process. They provide a secure bond that holds indoor and outdoor signage in place, while also reducing wear-and-tear caused by vibration.

Appliances: Enhancing Aesthetics with Invisible Bonding

Trust in 3M™ VHB™ Tape to enhance the aesthetic appeal of appliances. Whether it’s bonding glass to metal or different materials together, these tapes ensure virtually invisible bonding. They maintain a stronger holding power, providing a sleek and seamless finish to appliances.

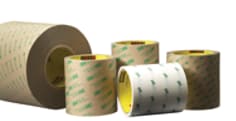

Featured Products

To cater to diverse bonding needs, 3M™ offers a range of specialized VHB™ Tape products. Let’s explore some of their featured products:

1. 3M™ VHB™ Tape GPH Family

This tape family excels in high-temperature performance, making it ideal for applications involving paint bake cycles and high operating temperatures. It is commonly used for bonding stiffeners to architectural metal panels, elevator door panels, equipment enclosures, metal cabinets, appliances, and signage.

2. 3M™ VHB™ Thin Foam Tape

Engineered with a uniquely thin form, 3M™ VHB™ Thin Foam Tapes are perfect for applications that require a low-profile bonding solution. They find common use in bonding LCD, OLED, lens, and touch-panel displays, logo attachments, and point-of-purchase/display construction.

3. 3M™ VHB™ RP Product Family

The RP Product Family offers a general-purpose adhesive with the performance of 3M™ VHB™ Tape. It is designed to meet a wide range of bonding needs across different industries.

4. 3M™ VHB™ Structural Glazing Tape

Engineered specifically for structural glazing applications, this tape is a durable and high-performance solution. It provides strong and reliable bonding of glass panels into curtain wall systems, commercial windows and doors, and skylight/canopy systems. It offers significant value to contract glazers and glazing system manufacturers.

Image Source 3M